What Is An Electrical Isolator Switch?

An electrical isolator switch is a mechanical device used to disconnect a part of an electrical circuit from the main power supply. It functions primarily as a safety mechanism, allowing for the safe maintenance and inspection of electrical systems by ensuring that a particular section of the circuit is entirely de-energized.

In electrical systems, the importance of isolator switches lies in their role in safeguarding personnel and equipment. By providing a visible and reliable means of isolating specific parts of a circuit, they help prevent accidental contact with live electrical components, reducing the risk of electric shock and equipment damage. Isolator switches are generally employed in conjunction with other protective devices, such as circuit breakers, to enhance overall system safety.

Common applications of electrical isolator switches include industrial environments where large machinery and high-voltage equipment require periodic maintenance, as well as in residential and commercial settings for isolating smaller circuits. They are also used in power distribution systems to ensure that maintenance can be carried out without affecting the entire network.

Basic Functionality of Electrical Isolator Switches

The primary purpose of an electrical isolator switch is to isolate specific parts of an electrical circuit, ensuring that those sections can be safely maintained, inspected, or repaired without the risk of electrical shock or damage. By disconnecting a portion of the circuit from the main power supply, the isolator switch creates a physical gap that prevents the flow of current, thereby securing the area for safe work.

Isolators vs. Circuit Breakers

While both isolators and circuit breakers serve protective functions in electrical systems, their roles are distinct. A circuit breaker is designed to automatically interrupt the flow of electricity in response to abnormal conditions such as an overload or short circuit. It provides protection by cutting off power when a fault is detected. In contrast, an isolator switch is used to manually disconnect a circuit for safety purposes. It does not provide automatic protection and is typically operated when the circuit is already de-energized.

Types of Isolation

Isolator switches can be categorized based on their method of operation:

Manual Isolation: Involves the physical operation of the switch by an individual. The switch is manually moved to the "open" position to break the circuit and isolate the electrical components. This type is commonly used in applications where the isolation process is infrequent or where a high level of control is required.

Automated Isolation: Utilizes electrical or mechanical systems to automatically operate the isolator switch. This type is often employed in complex or large-scale systems where quick and reliable isolation is necessary, or where human intervention is limited. Automated isolators can be integrated into control systems to allow for remote operation.

Types of Electrical Isolator Switches

Electrical isolator switches come in various types, each designed to suit specific applications based on the number of poles and the nature of the electrical circuit they are intended to isolate.

Single-Pole Isolator Switch

A single-pole isolator switch is designed to disconnect only one live wire in a circuit. It is typically used in single-phase circuits, where the electrical system involves one live wire and one neutral wire. These switches are commonly employed in residential and light commercial applications to isolate individual circuits, such as lighting or small appliances, ensuring that maintenance can be conducted safely.

Double-Pole Isolator Switch

The double-pole isolator switch is capable of disconnecting both live wires in a double-phase circuit. This type of switch is often used in applications where it is necessary to isolate both the live and neutral wires simultaneously, providing a more comprehensive disconnection. Double-pole isolators are frequently used in residential and commercial settings, particularly for circuits that power high-demand appliances, such as ovens or water heaters, where complete isolation is required.

Three-Pole Isolator Switch

A three-pole isolator switch is designed for use in three-phase circuits, which are commonly found in industrial and commercial power distribution systems. Three-phase circuits involve three live wires, and the three-pole switch disconnects all three simultaneously. This type of isolator switch is essential in applications where large machinery or heavy equipment operates on three-phase power, ensuring that the equipment can be fully isolated for maintenance or in emergency situations.

Four-Pole Isolator Switch

The four-pole isolator switch is used in more complex industrial applications where both three-phase power and a neutral wire need to be isolated. This type of switch disconnects all three live wires along with the neutral wire, providing comprehensive isolation for equipment that requires both power and neutral disconnection. Four-pole isolator switches are commonly used in industrial environments where safety and operational integrity are paramount, particularly in systems where neutral wire disconnection is necessary for safety or operational reasons.

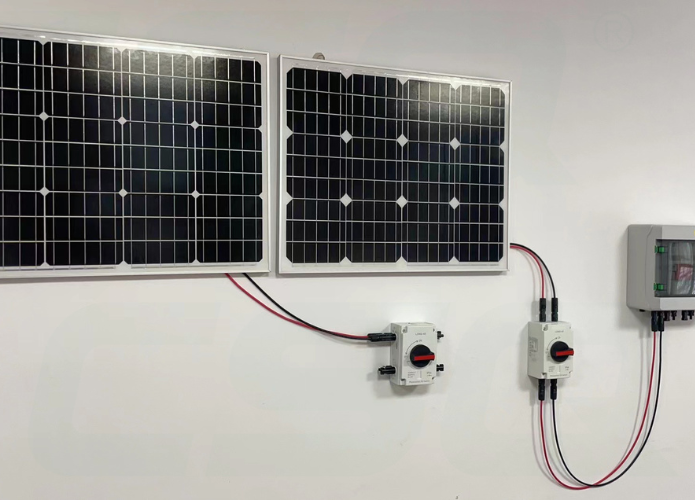

CSQ Electric DC Isolator Switches

Components of an Electrical Isolator Switch

An electrical isolator switch is composed of several key components that work together to safely disconnect electrical circuits. Each component plays a specific role in ensuring the switch operates effectively and reliably.

Contacts

Contacts are the most critical components of an electrical isolator switch. They are the conductive parts that physically connect or disconnect the electrical circuit. When the switch is in the "closed" position, the contacts touch, allowing current to flow through the circuit. When the switch is operated to the "open" position, the contacts separate, breaking the circuit and isolating the connected equipment from the power source. The material and design of the contacts are crucial for ensuring they can handle the electrical load without degradation over time.

Operating Mechanism

The operating mechanism is the part of the isolator switch that controls the movement of the contacts. This mechanism can be manual, where the operator physically moves a lever or handle to open or close the switch, or it can be automated, driven by an electrical or mechanical system. The design of the operating mechanism ensures that the contacts move smoothly and reliably, with sufficient force to maintain a secure connection or disconnection as required.

Enclosure (if any)

In many cases, an electrical isolator switch is housed within an enclosure. The enclosure provides physical protection for the switch components, shielding them from environmental factors such as dust, moisture, and mechanical damage. It also serves as a safety measure, preventing accidental contact with live parts and reducing the risk of electric shock. The material of the enclosure is typically non-conductive and durable, such as plastic or metal with an insulating coating, to ensure long-term protection and reliability.

Insulating Materials

Insulating materials are used throughout the isolator switch to prevent unintended electrical conduction. These materials are non-conductive and are applied to parts of the switch that must not carry current, such as the operating mechanism, the housing around the contacts, and the enclosure. Insulation ensures that the electrical path is confined to the contacts and wiring, preventing short circuits and protecting users from electrical hazards.

Working Principle of an Electrical Isolator Switch

The working principle of an electrical isolator switch revolves around its ability to safely isolate a section of an electrical circuit from the power source, ensuring that maintenance or inspection can be conducted without the risk of electrical shock or damage.

How the Switch Isolates a Circuit

When an isolator switch is operated, it physically separates the electrical contacts within the switch. This separation creates a gap that interrupts the flow of electrical current, effectively isolating the circuit. The circuit remains open as long as the contacts are apart, preventing any electrical energy from passing through and ensuring that the connected equipment or section of the circuit is de-energized.

The Role of Contacts in Breaking the Circuit

The contacts within the isolator switch are the critical components responsible for breaking and making the circuit. When the switch is in the "closed" position, the contacts are pressed together, allowing electrical current to flow uninterrupted. When the switch is moved to the "open" position, the contacts are physically separated, breaking the circuit and stopping the flow of current. The design and material of the contacts ensure they can handle the required electrical load without overheating or deteriorating, providing a reliable means of disconnection.

Mechanical vs. Electrical Isolation

Isolation can be achieved through different methods:

Mechanical Isolation: This involves the physical separation of contacts within the switch. The operator manually or mechanically moves the switch to the "open" position, ensuring that there is a visible and clear break in the circuit. Mechanical isolation is often preferred in situations where it is important to visibly verify that the circuit is disconnected.

Electrical Isolation: In some advanced systems, isolation can be achieved electrically, where the switch is operated remotely or automatically via an electrical control signal. This method allows for quicker and more convenient isolation, especially in complex or large-scale systems. However, the principle remains the same: the electrical control ultimately causes the physical separation of contacts, ensuring that the circuit is safely isolated.

Applications of Electrical Isolator Switches

Electrical isolator switches are used across various settings to ensure the safe and effective disconnection of electrical circuits. Their applications range from heavy industrial environments to residential and commercial settings, where they play a critical role in maintaining safety and operational efficiency.

Industrial Applications

In industrial environments, electrical isolator switches are crucial for the maintenance of heavy machinery and equipment. These switches are used to isolate large sections of electrical systems, allowing maintenance personnel to work on equipment without the risk of accidental energization. For example, in manufacturing plants, isolator switches are often installed on circuits that supply power to high-voltage machinery. Before any maintenance work begins, the isolator switch is used to disconnect the equipment from the power supply, ensuring that it is completely safe to handle. This practice helps prevent accidents and equipment damage during maintenance and repair activities.

Residential Applications

In residential settings, electrical isolator switches are used within domestic electrical systems to enhance safety. These switches can be found in home electrical panels where they isolate circuits for appliances, lighting, or other electrical systems. For instance, an isolator switch might be used to disconnect power to a water heater or an air conditioning unit during maintenance. By providing a clear and reliable means of disconnecting power, isolator switches help homeowners and electricians perform maintenance tasks safely, reducing the risk of electric shock or other hazards.

Commercial Applications

In commercial buildings and complexes, electrical isolator switches are commonly employed to manage power distribution and ensure safety across multiple circuits. These switches are used in settings such as office buildings, shopping centers, and hotels, where various electrical systems need to be maintained or upgraded without disrupting the entire power supply. For example, in a commercial building, isolator switches might be installed on circuits supplying power to HVAC systems, elevators, or lighting controls. During routine maintenance or in the event of an emergency, these switches can be used to isolate specific areas or systems, allowing work to be conducted safely and efficiently without affecting other parts of the building.

Advantages of Using Electrical Isolator Switches

Electrical isolator switches offer several important benefits, particularly in the areas of safety and operational effectiveness. These advantages make them a valuable component in many electrical systems, from industrial setups to residential and commercial applications.

Enhanced Safety During Maintenance

One of the primary advantages of using electrical isolator switches is the enhanced safety they provide during maintenance activities. By isolating specific parts of an electrical circuit, these switches ensure that maintenance personnel can work on equipment without the risk of accidental energization. This reduces the likelihood of electric shock, equipment damage, and other hazards associated with live circuits. Isolator switches provide a straightforward and reliable method for de-energizing circuits, which is critical for maintaining a safe working environment.

Prevents Accidental Contact with Live Circuits

Electrical isolator switches are effective in preventing accidental contact with live circuits. When the switch is in the "open" position, it creates a physical gap in the circuit, ensuring that no electrical current can flow through. This clear disconnection helps prevent accidents that could occur if someone inadvertently comes into contact with live electrical components. The visible separation provided by isolator switches makes it easy to confirm that a circuit is safely isolated, further reducing the risk of accidental exposure to electricity.

Ensures Clear Separation of Electrical Circuits

Another advantage of electrical isolator switches is their ability to ensure clear separation of electrical circuits. This separation is essential for both safety and operational reasons. In complex electrical systems, isolator switches can be used to divide circuits into manageable sections, allowing maintenance or troubleshooting to be performed on one part of the system without affecting the rest. This clear and reliable isolation is particularly important in settings where multiple circuits are in close proximity or where different parts of a system need to be independently controlled and maintained.

Limitations and Challenges of Electrical Isolator Switches

While electrical isolator switches are valuable tools for ensuring safety and circuit isolation, they do have certain limitations and challenges that need to be considered in their application.

Not Designed to Interrupt a Load or Current

One of the key limitations of electrical isolator switches is that they are not designed to interrupt a load or current. Isolator switches are typically operated when the circuit is already de-energized, meaning that they are not intended to break an active electrical connection under load conditions. Attempting to open an isolator switch while current is flowing can cause arcing, which may damage the switch and pose safety risks. This limitation means that isolator switches must be used in conjunction with other protective devices, such as circuit breakers, which are specifically designed to safely interrupt electrical current under load.

Requires Additional Devices for Full Protection

Another challenge associated with electrical isolator switches is that they require additional devices for full electrical protection. While isolator switches are effective at providing physical separation and isolation of circuits, they do not offer protection against faults such as overcurrent, short circuits, or electrical surges. To achieve comprehensive protection, isolator switches need to be used in combination with circuit breakers, fuses, or other protective devices that can detect and respond to electrical faults. This requirement adds complexity to the design and installation of electrical systems, as multiple components must work together to ensure safety and reliability.

Manual Operation May Lead to Human Error

The manual operation of many electrical isolator switches can introduce the potential for human error. For instance, an operator might forget to isolate the circuit before starting maintenance work, or they may accidentally close the switch too early, reconnecting the circuit while it is still being serviced. These errors can lead to dangerous situations, including electric shock or equipment damage. While some isolator switches are designed for automated or remote operation, which can reduce the risk of human error, manual switches are still widely used and require careful handling and adherence to safety protocols.

Conclusion

An electrical isolator switch is a crucial component in various electrical systems, designed to provide a safe and reliable means of disconnecting circuits for maintenance, inspection, or emergency purposes. By physically separating the electrical contacts, isolator switches ensure that specific sections of a circuit are completely de-energized, thereby protecting personnel and equipment from the dangers associated with live electrical components.

While these switches are essential for enhancing safety during maintenance and preventing accidental contact with live circuits, they do have certain limitations. They are not intended to interrupt current under load, requiring additional protective devices like circuit breakers to ensure full system protection. Additionally, the manual operation of isolator switches can introduce the risk of human error, making it important to follow proper safety protocols.

In summary, electrical isolator switches play a vital role in safeguarding electrical systems across industrial, residential, and commercial applications. Their ability to clearly and effectively isolate circuits makes them indispensable in maintaining the safety and integrity of electrical operations.

CSQ Electric: A Leading Isolator Switches Supplier

CSQ Electric is a prominent supplier specializing in isolator switches, offering a diverse range of products designed to meet various electrical isolation needs. Known for their commitment to quality and reliability, CSQ Electric provides solutions for industrial, residential, and commercial applications.

Product Range

CSQ Electric supplies a comprehensive selection of isolator switches, including:

* Single-Pole Isolator Switches: For use in single-phase circuits, ideal for residential and light commercial applications.

* Double-Pole Isolator Switches: Suitable for double-phase circuits, providing isolation for both live and neutral wires.

* Three-Pole Isolator Switches: Designed for three-phase circuits, essential for industrial machinery and equipment.

* Four-Pole Isolator Switches: Used in complex systems requiring isolation of all three live wires plus the neutral wire.

Key Attributes

* Quality Assurance: CSQ Electric's isolator switches are manufactured to meet high industry standards, ensuring durability and reliable performance in various environments.

* Innovative Design: Their switches feature advanced designs for ease of use and enhanced safety, including clear isolation indicators and robust construction.

* Custom Solutions: CSQ Electric offers tailored solutions to meet specific client requirements, accommodating diverse electrical systems and operational needs.

Applications

CSQ Electric's isolator switches are utilized across multiple sectors:

* Industrial: For isolating power to heavy machinery, ensuring safe maintenance and operation.

* Residential: To isolate circuits for home appliances and lighting, enhancing safety during repairs and upgrades.

* Commercial: Managing power distribution in office buildings, retail spaces, and other commercial facilities.

In summary, CSQ Electric stands out as a reliable supplier of isolator switches, providing high-quality products designed to ensure safety and efficiency in electrical systems. Their extensive range and commitment to innovation make them a trusted partner for various electrical isolation needs.

Popular CSQ Electric Products

Get Price of Low-Voltage Electrical Products

Power Distribution System

- Automatic Transfer Switches (ATS)

- Manual Transfer Switches (MTS)

- Load Break Switches

- Fuse Switch Disconnector

- Molded Case Circuit Breaker (MCCB)

- Miniature Circuit Breaker (MCB)

- Residual Current Circuit Breaker With Overcurrent Protection (RCBO)

View All→

Industrial Control System

- Time Relays

- Monitoring Relays

- Other Relays

- AC Contactors

- Motor Control And Protection

- Thermal Overload Relay

View All→

Headquarter:

No.198, Wei 3rd Road, Economic Development Zone of Yueqing, Wenzhou City, China

Hangzhou Branch:

1601-3A, Unit 1, Building 1, Ruiling The World, Xiaoshan District, Hangzhou City, China

Copyright ©Siqi Technology Co., Ltd. All Rights Reserved.