How Molded Case Circuit Breakers Work: Types, Features, And Functions

Introduction

Electrical safety is a crucial consideration in any power distribution system, whether in homes, commercial buildings, or industrial facilities. Circuit breakers play a fundamental role in protecting electrical circuits from excessive current, short circuits, and other faults that could lead to fires, equipment damage, or power outages.

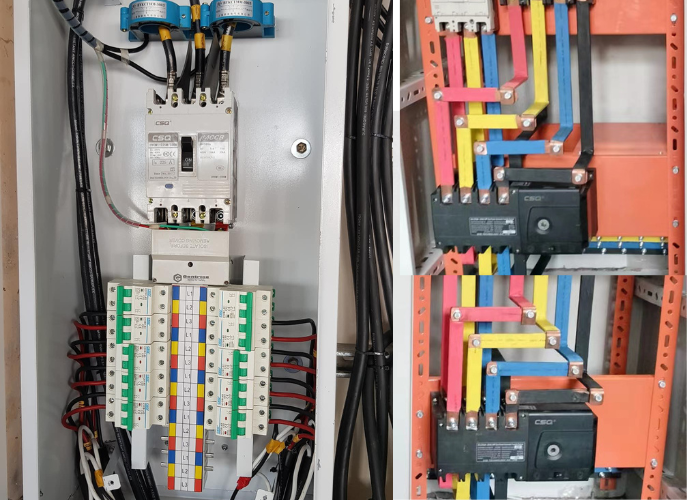

One of the most widely used circuit breakers in modern electrical systems is the Molded Case Circuit Breaker (MCCB). These breakers are known for their robust protection, high breaking capacity, and ability to be reset and reused after a trip event.

In this comprehensive guide, we will explore:

The fundamental working principle of MCCBs.

The Molded Case Circuit Breaker Function and how it protects electrical systems.

The different Molded Case Circuit Breaker Types available.

Key features that make MCCBs a preferred choice over other circuit breakers.

Applications, selection criteria, and maintenance practices to maximize their performance.

By the end of this guide, you will have a deep understanding of MCCBs and their significance in modern electrical safety.

What is a Molded Case Circuit Breaker (MCCB)?

A Molded Case Circuit Breaker (MCCB) is an electrical protection device designed to interrupt current flow in a circuit when an overcurrent or short circuit condition is detected. Unlike traditional fuses that require replacement after tripping, MCCBs can be reset and reused, offering long-term cost savings and increased reliability.

1.Key Characteristics of MCCBs

MCCBs have several distinct characteristics that make them suitable for a wide range of applications:

Encased in a Molded Insulating Shell: The name "molded case" refers to the durable insulating enclosure that houses the internal components, providing protection from environmental factors like dust, moisture, and mechanical damage.

Uses Thermal-Magnetic Trip Mechanisms: MCCBs typically employ a combination of thermal (overload protection) and magnetic (short circuit protection) trip units for reliable operation.

High Breaking Capacity: They can handle high fault currents without sustaining damage.

Adjustable Trip Settings: Some MCCBs offer customizable trip thresholds, allowing flexibility in different applications.

Wide Range of Current Ratings: MCCBs are available in ratings from 15A to over 2500A, making them suitable for both small and large-scale electrical systems.

Molded Case Circuit Breaker Function

MCCBs perform several key functions in electrical systems to ensure safety and reliability.

1 Overload Protection

One of the primary functions of an MCCB is to prevent overcurrent conditions caused by excessive loads on an electrical circuit.

MCCBs monitor current flow and trip when the load exceeds the rated current for an extended period.

The thermal trip mechanism consists of a bimetallic strip that bends when exposed to excessive heat. This bending action triggers the breaker to open the circuit and stop current flow.

Overload protection prevents overheating, damage to conductors, and potential fire hazards in electrical systems.

2 Short Circuit Protection

Short circuits occur when an unintended low-resistance path forms between two conductors, leading to a sudden surge of current.

MCCBs detect this sudden spike in current and respond within milliseconds to disconnect the faulty circuit.

The magnetic trip mechanism consists of an electromagnetic coil, which creates a strong magnetic force when current exceeds a critical level. This force instantly trips the breaker, preventing catastrophic damage.

3 Circuit Isolation

MCCBs also serve as manual isolation devices that allow electricians to safely perform maintenance on electrical equipment.

By switching off an MCCB, technicians can work on circuits without the risk of accidental re-energization.

This function is especially important in industrial and commercial facilities, where scheduled maintenance and system upgrades are frequent.

Molded Case Circuit Breaker Types

There are multiple Molded Case Circuit Breaker Types, each designed for specific applications. Understanding these types helps in selecting the right breaker for a given electrical system.

1 Standard MCCBs

The most widely used type, found in residential, commercial, and industrial applications.

Provides basic overload and short circuit protection.

Used in panelboards, switchboards, and motor control centers.

2 Current-Limiting MCCBs

Designed to reduce the energy released during a short circuit by limiting the fault current.

Protects equipment from thermal and mechanical stress caused by high fault currents.

Common in industrial settings and high-power electrical systems.

3 Motor Protection MCCBs

Specially designed to protect electric motors from overload and phase failure.

Features adjustable thermal trip settings to match the motor’s full load current.

Prevents overheating and damage to motor windings.

4 Earth Leakage MCCBs

Provides protection against ground faults and leakage currents.

Helps prevent electric shocks and fire hazards due to insulation failures.

Used in chemical plants, hospitals, and data centers where electrical safety is critical.

5 Electronic MCCBs

Uses electronic trip units for precise protection.

Offers advanced features like real-time monitoring, remote control, and event logging.

Ideal for smart grids, automation, and industrial power management.

Key Features of Molded Case Circuit Breakers

MCCBs offer several advanced features that enhance their reliability and efficiency.

1 Adjustable Trip Settings

Allows users to fine-tune protection settings based on system requirements.

Enhances flexibility in different applications.

2 High Breaking Capacity

MCCBs can handle and interrupt high fault currents, preventing catastrophic damage to electrical systems.

3 Compact and Durable Design

Despite their robust protection, MCCBs are relatively compact, making them suitable for confined spaces.

4 Remote Monitoring and Control

Advanced MCCBs allow for remote operation and fault diagnostics, improving system efficiency.

Applications of MCCBs

MCCBs are used in a variety of industries and settings, including:

Industrial Facilities

Protecting heavy machinery and motors.

Ensuring stable power distribution.

Commercial Buildings

Safeguarding office equipment and HVAC systems.

Enhancing safety in large electrical networks.

Renewable Energy Systems

Protecting solar inverters and battery banks.

Data Centers

Preventing power failures by safeguarding critical infrastructure.

How to Select the Right MCCB?

When choosing an MCCB, consider the following factors:

Rated Current (In): Must match the expected circuit load.

Breaking Capacity (Icu): Should be higher than the prospective fault current.

Number of Poles: Choose between single-pole, two-pole, three-pole, or four-pole based on the system configuration.

Trip Unit Type: Thermal-magnetic vs. electronic trip units.

Environmental Conditions: Consider humidity, temperature, and exposure to dust or corrosive elements.

Conclusion

Molded Case Circuit Breakers are critical safety devices in electrical systems. Understanding Molded Case Circuit Breaker Types and Molded Case Circuit Breaker Function ensures the right selection for a given application. With proper installation and maintenance, MCCBs provide long-term reliability, enhanced safety, and cost-effective protection for electrical networks.

Popular CSQ Electric Products

Get Price of Low-Voltage Electrical Products

Power Distribution System

- Automatic Transfer Switches (ATS)

- Manual Transfer Switches (MTS)

- Load Break Switches

- Fuse Switch Disconnector

- Molded Case Circuit Breaker (MCCB)

- Miniature Circuit Breaker (MCB)

- Residual Current Circuit Breaker With Overcurrent Protection (RCBO)

View All→

Industrial Control System

- Time Relays

- Monitoring Relays

- Other Relays

- AC Contactors

- Motor Control And Protection

- Thermal Overload Relay

View All→

Headquarter:

No.198, Wei 3rd Road, Economic Development Zone of Yueqing, Wenzhou City, China

Hangzhou Branch:

1601-3A, Unit 1, Building 1, Ruiling The World, Xiaoshan District, Hangzhou City, China

Copyright ©Siqi Technology Co., Ltd. All Rights Reserved.